Markets

Broad range of applications

Spectroscopic technology has a broad number of applications in various market niches. We list a variety of our markets below

Food sorting

Pharmaceutical market

One of our pharmaceutical applications is sorting pills. As the molecular structure of pills has spectroscopic features, the Prism Spectroscopic Imaging cameras are useful for quality sorting.

Automotive painting

Foreign body sorting

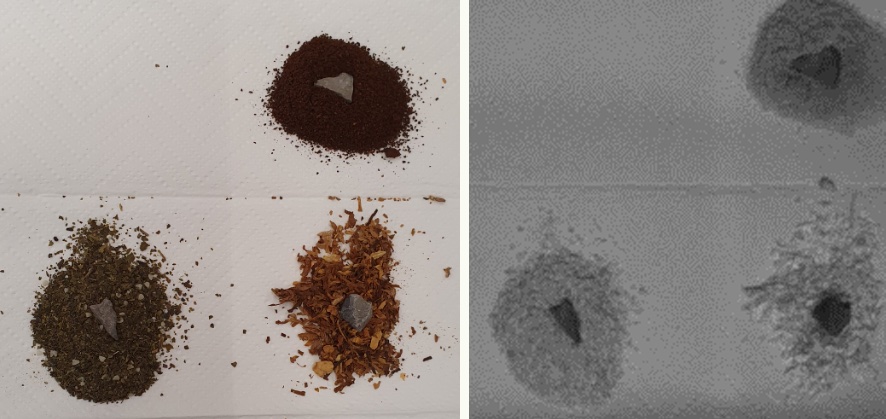

Products like Tea leaves, Coffee beans and Tobacco leaves need to be separated from stones during the production process. The Dual camera has the ability to scan your product and support your software in excluding the stones from your product.

Detecting foreign material:

Custom Designs

Besides of the mainstream spectroscopic cameras BlueVision designs on request also highly customized camera modules for OEMs or research applications. To give you an idea of custom designs, we list a few examples:

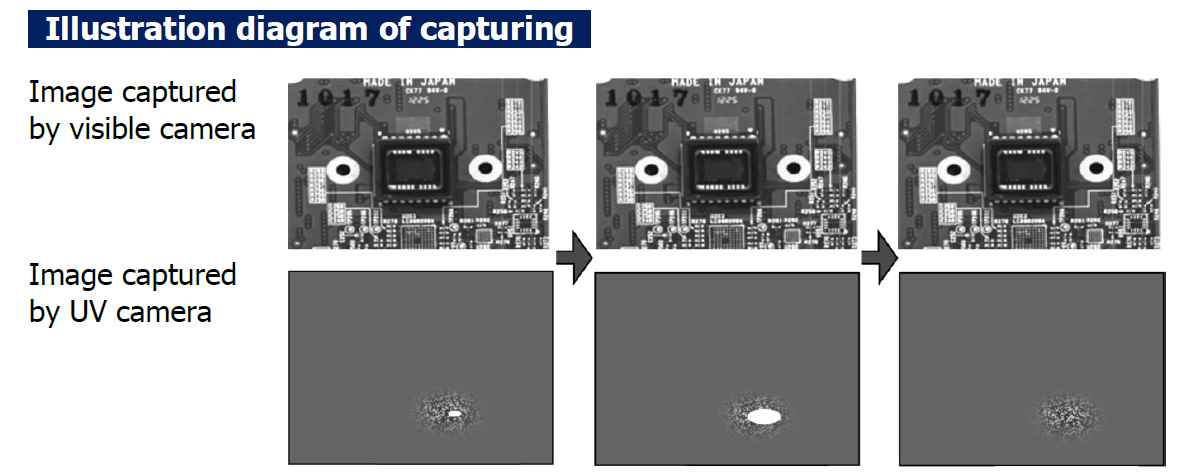

Electro-Static Discharge detection camera.

ESD can create spectacular electric sparks (lightning, with the accompanying sound of thunder), but it is the less dramatic forms which may cause huge damages to sensitive electronic devices. As ESD is a difficult phenomenon in your process and hard to detect our customers are struggling with solving the cause.

ESD can cause harmful effects of importance in industry, including explosions in gas, fuel vapor and coal dust, as well as failure of solid-state electronics components such as integrated circuits. These can suffer permanent damage when subjected to high voltages.

Based on Prism Spectroscopic Imaging ESD can be detected @ 0,8uJoule at 1 Meter.

Click below on the image to view an ESD experiment

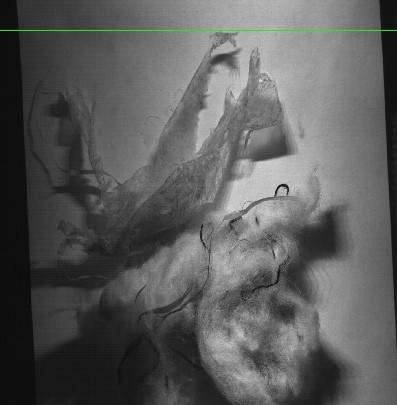

High-End Surveillance

We have over 10 years of experience in the High-End Surveillance (ruggedized) market. Multi-sensor equipment is necessary in demanding applications like homeland security. Prism spectroscopic solutions like RGB combined with NIR and or InGaAs technology creates compacted high-end sensors. At these products export regulations comply

Cotton inspection

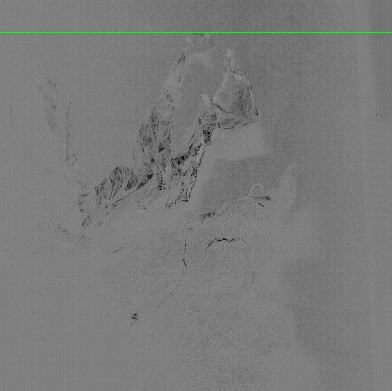

During the process of sorting Cotton it is needed to find the wet and also plastic parts in the product. The dual camera with P/S technology is used to find the contamination.

The pictures below show reflection in the P wave image. The subtracted image S-P wave shows difference which is the contaminated area. In this example the transparent plastic part is easy to detect.

Example for Shinny contaminants detection (in Cotton)

.

.  .

.

P wave image S wave image S-P wave image

Other similar applications are inspecting shiny paper, water, seal defect (scratch, bubble) or printing inspection, mineral analysis and contaminants inspection.